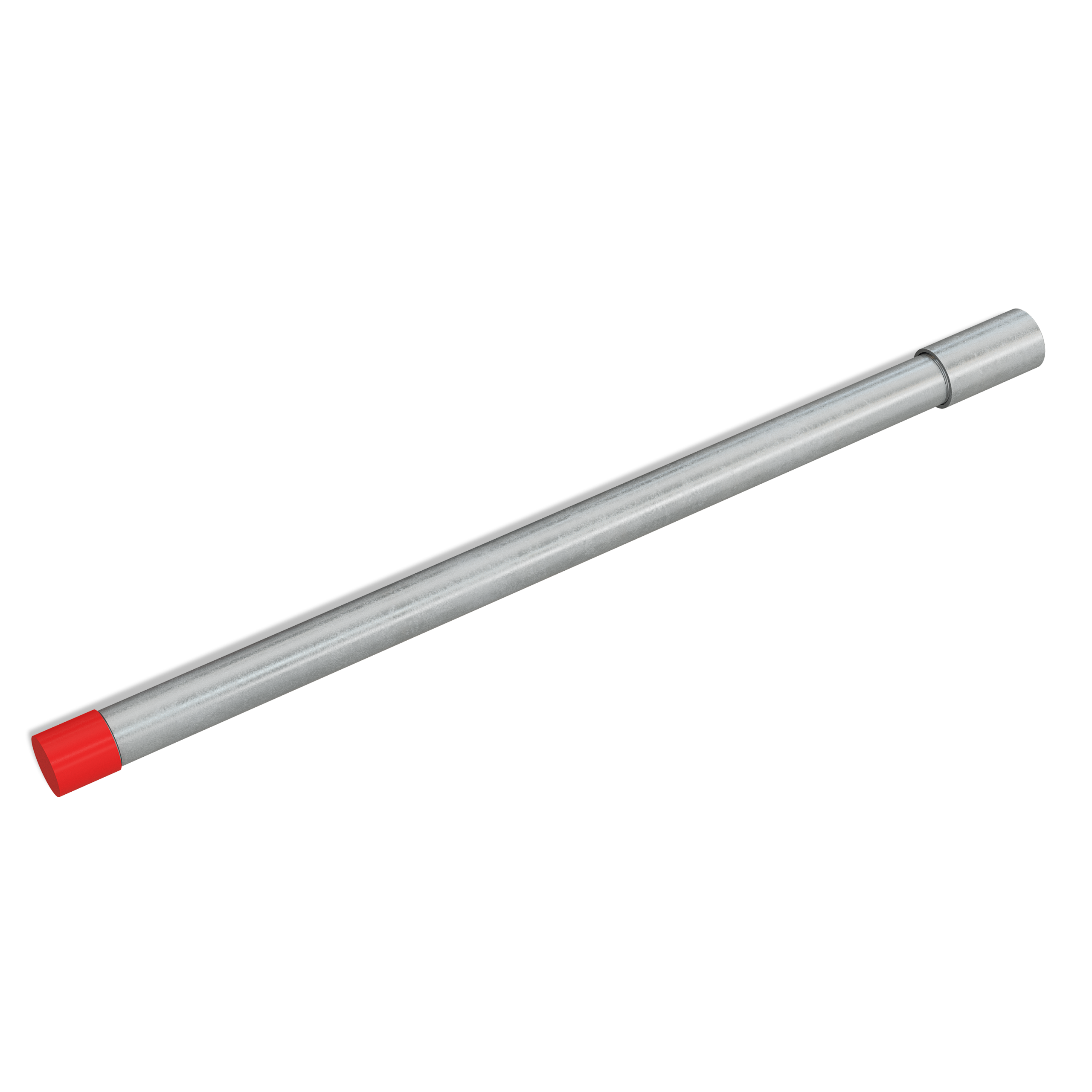

Rigid Steel Conduit Nipple

Product Features

-

Overview

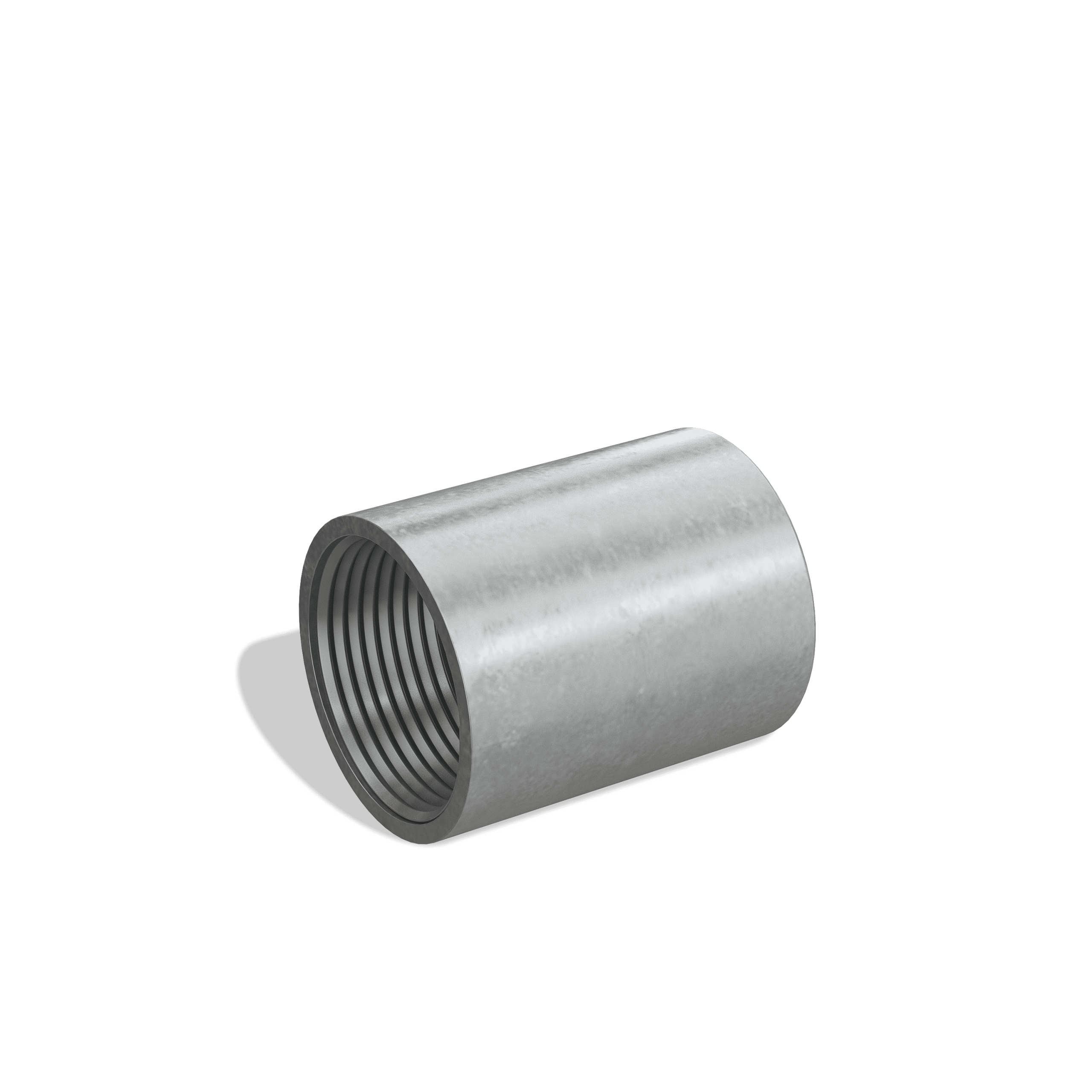

Galvanized Rigid Conduit (GRC) Nipples are to be installed on conduit raceways systems for the interconnection of conduit runs and other fittings. Available in custom lengths. Nipples provide a secure connection between conduit sections and fittings, ensuring proper alignment and continuity of the conduit system. -

Consistent Quality

Made from high-quality flat rolled steel utilizing high production tube mills utilizing the electric resistance welding method. Uniform galvanized protection and smoothness on the interior and exterior coatings. The inside surface is obstruction free and smooth to reduce friction between conduit wall and wire. Manufactured for long life – durable and strong. No flaking or chipping when subjected to extreme stress. -

Locations

RMC’s rigid conduit nipples meet the requirements of National Electrical Code Article 344 for use in indoor and outdoor locations and in wet and dry locations, including Class 1 Division 1 Hazardous Locations. Rigid conduit provides exceptional physical protection, reduces exposure to EMF and shields against electromagnetic interference. -

Lower Life-Cycle Costs

Hot dipped galvanized coating provides enhanced corrosion protection. Physical and mechanical properties ensure that the pipe has an extended life cycle. Resists cracking, flaking, peeling, impact, and damage from severe bending. Impact-resistant and non-combustible. 100% Recyclable. -

Listings

Underwriters Laboratories Standard for rigid conduit nipples (UL6) file # E531580. American National Standards Institute (ANSI® C80.1). National Electric Code® Article 344. Additional information can be found in the Underwriters Laboratories Inc., General information for Electrical Equipment Directory. The UL product category for Rigid is DYIX.

| Item # | UPC | Size | Length (in.) | Std. Carton Qty | Master Carton Qty | Weight per 100 (lbs.) |

|---|---|---|---|---|---|---|

| RMCNP0512 | 0081013870001 | 1/2″ | 1-1/4″ | 25 | 600 | 6 |

| RMCNP0520 | 0081013870002 | 1/2″ | 2″ | 25 | 600 | 12 |

| RMCNP0525 | 0081013870003 | 1/2″ | 2-1/2″ | 25 | 400 | 15 |

| RMCNP0530 | 0081013870004 | 1/2″ | 3″ | 25 | 400 | 19 |

| RMCNP0712 | 0081013870005 | 3/4″ | 1-1/4″ | 25 | 400 | 9 |

| RMCNP0720 | 0081013870006 | 3/4″ | 2″ | 25 | 300 | 14 |

| RMCNP0725 | 0081013870007 | 3/4″ | 2-1/2″ | 25 | 300 | 19 |

| RMCNP0730 | 0081013870008 | 3/4″ | 3″ | 25 | 200 | 24 |

| RMCNP1015 | 0081013870009 | 1″ | 1-1/2″ | 25 | 300 | 16 |

| RMCNP1020 | 0081013870010 | 1″ | 2″ | 25 | 200 | 22 |

| RMCNP1025 | 0081013870011 | 1″ | 2-1/2″ | 25 | 200 | 28 |

| RMCNP1030 | 0081013870012 | 1″ | 3″ | 25 | 150 | 36 |

| RMCNP1217 | 0081013870013 | 1-1/4″ | 1-3/4″ | 25 | 150 | 22 |

| RMCNP1220 | 0081013870014 | 1-1/4″ | 2″ | 25 | 150 | 28 |

| RMCNP1225 | 0081013870015 | 1-1/4″ | 2-1/2″ | 25 | 150 | 37 |

| RMCNP1230 | 0081013870016 | 1-1/4″ | 3″ | 25 | 100 | 47 |

| RMCNP1517 | 0081013870017 | 1-1/2″ | 1-3/4″ | 25 | 100 | 28 |

| RMCNP1520 | 0081013870018 | 1-1/2″ | 2″ | 25 | 75 | 34 |

| RMCNP1525 | 0081013870019 | 1-1/2″ | 2-1/2″ | 25 | 75 | 44 |

| RMCNP1530 | 0081013870020 | 1-1/2″ | 3″ | 25 | 50 | 56 |

| RMCNP2020 | 0081013870021 | 2″ | 2″ | 25 | 75 | 44 |

| RMCNP2025 | 0081013870022 | 2″ | 2-1/2″ | 25 | 50 | 59 |

| RMCNP2030 | 0081013870023 | 2″ | 3″ | 25 | 50 | 72 |

| RMCNP2525 | 0081013870024 | 2-1/2″ | 2-1/2″ | – | 40 | 84 |

| RMCNP3027 | 0081013870025 | 3″ | 2-3/4″ | – | 30 | 118 |

| RMCNP3527 | 0081013870026 | 3-1/2″ | 2-3/4″ | – | 20 | 160 |

| RMCNP4028 | 0081013870027 | 4″ | 2-7/8″ | – | 20 | 180 |

| RMCNP5030 | 0081013870028 | 5″ | 3″ | – | 5 | 240 |

| RMCNP6031 | 0081013870029 | 6″ | 3-1/8″ | – | 5 | 350 |

Note: Lengths longer than 12″ and Special threads are available upon request. Both ends NPT threads conform to ANSI B1.20.1. Weights are approximate.