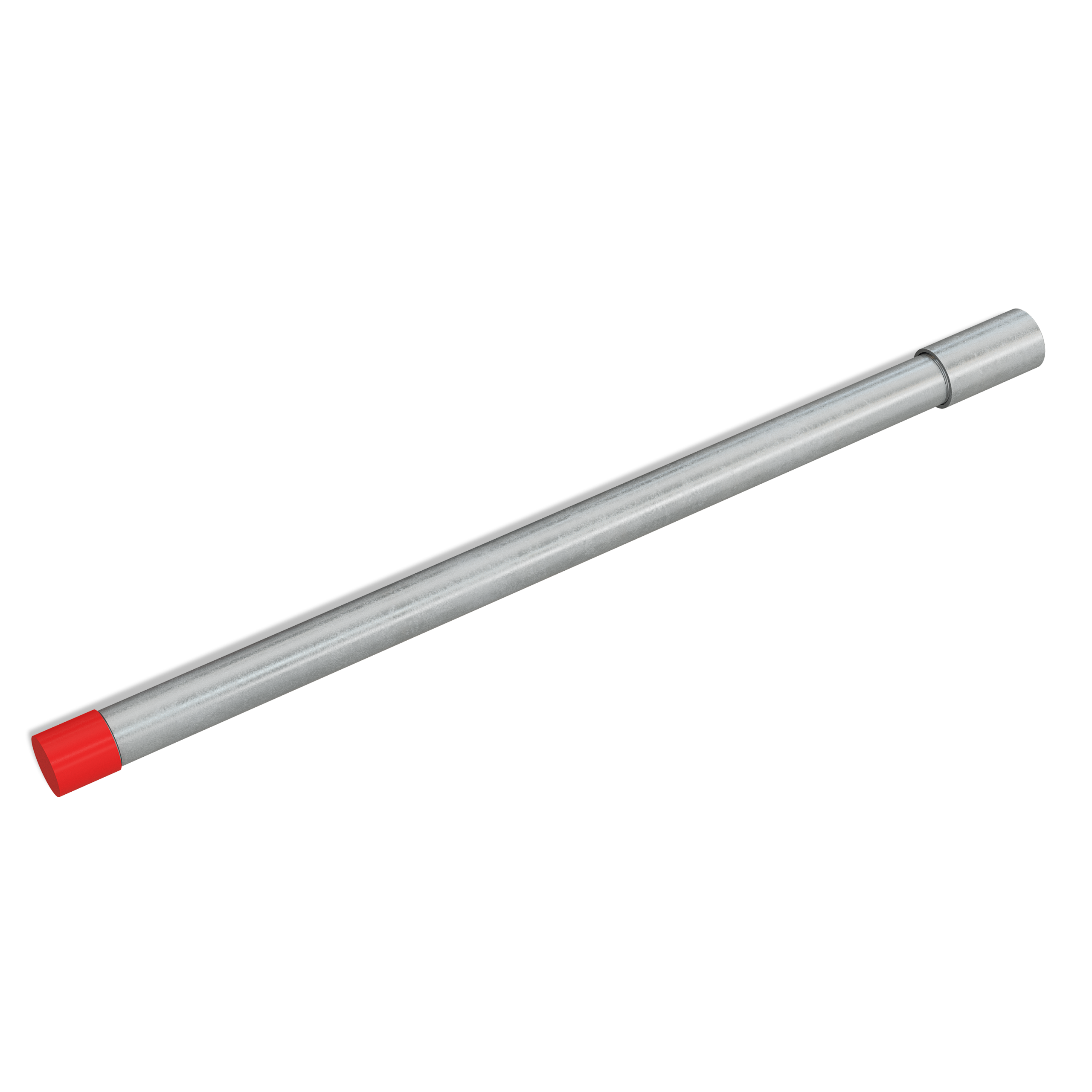

Rigid Conduit (GRC)

Product Features

-

Overview

RMC’s Galvanized Rigid Conduit (GRC) (UL6) has excellent protection, strength, and ductility for raceway systems. Our rigid conduit is manufactured from high strength hot-dipped galvanized steel and produced by the electrical resistance welding process which ensures continuous weld seams that will not split or crack at the weld and are free from interior defects. Our precision threaded ends ensure fast assembly in the field. -

Consistent Quality

Made from high-quality flat rolled steel utilizing high production tube mills utilizing the electric resistance welding method. Uniform galvanized protection and smoothness on the interior and exterior coatings. The inside surface is obstruction free and smooth to reduce friction between conduit wall and wire. Manufactured for long life – durable and strong. Threads are galvanized after cutting. No flaking or chipping when subjected to extreme stress. Easy to bend, cut and thread on the job. -

Locations

RMC’s rigid conduit meets the requirements of National Electrical Code Article 344 for use in indoor and outdoor locations and in wet and dry locations, including Class 1 Division 1 Hazardous Locations. Rigid conduit provides exceptional physical protection, reduces exposure to EMF and shields against electromagnetic interference. -

Lower Life-Cycle Costs

Hot dipped galvanized coating provides enhanced corrosion protection. Physical and mechanical properties ensure that the pipe has an extended life cycle. Resists cracking, flaking, peeling, impact, and damage from severe bending. Impact-resistant and non-combustible. 100% Recyclable. -

Listings

Underwriters Laboratories Standard for rigid conduit (UL6) file # E531580. American National Standards Institute (ANSI® C80.1). National Electric Code® Article 344. Additional information can be found in the Underwriters Laboratories Inc., General information for Electrical Equipment Directory. The UL product category for Rigid is DYIX.

Certifications

Underwriters Laboratories Standard for rigid conduit (UL6) file # E531580

American National Standards Institue (ANSI® C80.1)

National Electric Code® Article 344

Additional information can be found in the Underwriters Laboratories Inc., General information for Electrical Equipment Directory. The UL product category for Rigid is DYIX.

| Part Number | Trade Size | Nominal WT. Per 100FT (30.5M) | Nominal Outside Diameter | Nominal Wall Thickness | Color Tape | Quantity In Bundle | Quantity Per Lift | Weight/Lift (lbs.) |

|---|---|---|---|---|---|---|---|---|

| RMCCT05 | 1/2 | 82 lbs / 37.2 kg | 0.840 in. / 21.3 mm | 0.104 in. / 2.60 mm | Black | 100 | 2500 | 2050 |

| RMCCT07 | 3/4 | 109 lbs / 49.4 kg | 1.050 in. / 26.7 mm | 0.107 in. / 2.70 mm | Red | 50 | 2000 | 2178 |

| RMCCT10 | 1 | 161 lbs / 73.0 kg | 1.315 in. / 33.4 mm | 0.126 in. / 3.20 mm | Blue | 50 | 1250 | 2013 |

| RMCCT12 | 1-1/4 | 218 lbs / 98.9 kg | 1.660 in. / 42.2 mm | 0.133 in. / 3.40 mm | Red | – | 900 | 1962 |

| RMCCT15 | 1-1/2 | 263 lbs / 119 kg | 1.900 in. / 48.3 mm | 0.138 in. / 3.50 mm | Black | – | 800 | 2099 |

| RMCCT20 | 2 | 350 lbs / 159 kg | 2.375 in. / 60.3 mm | 0.146 in. / 3.70 mm | Blue | – | 600 | 2103 |

| RMCCT25 | 2-1/2 | 559 lbs / 254 kg | 2.875 in. / 73.0 mm | 0.193 in. / 4.90 mm | Black | – | 370 | 2072 |

| RMCCT30 | 3 | 727 lbs / 330 kg | 3.500 in. / 88.9 mm | 0.205 in. / 5.20 mm | Blue | – | 300 | 2183 |

| RMCCT35 | 3-1/2 | 880 lbs / 399 kg | 4.000 in. / 101.6 mm | 0.215 in. / 5.50 mm | Black | – | 250 | 2200 |

| RMCCT40 | 4 | 1030 lbs / 467 kg | 4.500 in. / 114.3 mm | 0.225 in. / 5.70 mm | Blue | – | 200 | 2059 |

| RMCCT50 | 5 | 1400 lbs / 635 kg | 5.563 in. / 141.3 mm | 0.245 in. / 6.20 mm | Blue | – | 150 | 2101 |

| RMCCT60 | 6 | 1840 lbs / 835 kg | 6.625 in. / 168.3 mm | 0.266 in. / 6.80 mm | Blue | – | 100 | 1841 |