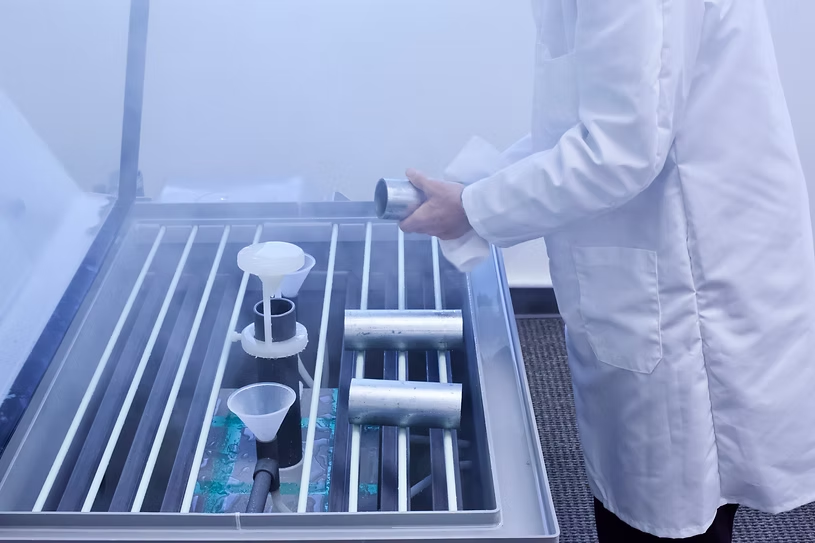

Testing procedures are in place from the time raw materials are received at the facility to when the finished conduit is packaged and readied for shipping.

- Rigorous Assessments

Every stage from procurement of raw material to final product delivery is examined thoroughly thanks to our team of experts. - Intensive Research and Development

Our goal is to continuously improve the quality of our products and innovate with new materials. - Internal Audits

We conduct official inspections to improve our quality control systems and best practices in order to deliver the latest in conduit technology.